Acoustic underlays help absorb these sounds, resulting in better room acoustics. For instance, Tecsound underlays are commonly used beneath concrete or screed subfloors to add an additional layer of soundproofing that is effective against vibration and noise. They are particularly effective when used with materials like ceramic tiles or floating floors, providing both sound insulation and comfort underfoot.

By selecting the right product for the specific noise control requirement, homeowners and businesses can create a quieter, more comfortable environment. They are particularly effective when used with materials like ceramic tiles or floating floors, providing both sound insulation and comfort underfoot. Looking to dampen noise in your office then use acoustic underlay under your floor.

These products provide greater efficiency in both heating and noise control, ensuring comfort throughout the year. These products provide greater efficiency in both heating and noise control, ensuring comfort throughout the year.

By choosing the right product for the specific noise control requirement, homeowners and businesses can create a quieter, more comfortable atmosphere. The use of recycled fibers and materials encourages recycling while reducing the environmental footprint of soundproofing installations.

Buildtec Acoustics offers underlays made from environmentally friendly materials, such as cork, recycled crumb rubber, and natural wool. In commercial environments, the reduction of noise pollution creates a more productive and pleasant working space, enhancing overall efficiency. Installing acoustic underlay beneath wood or laminate flooring can significantly reduce noise levels in rooms.

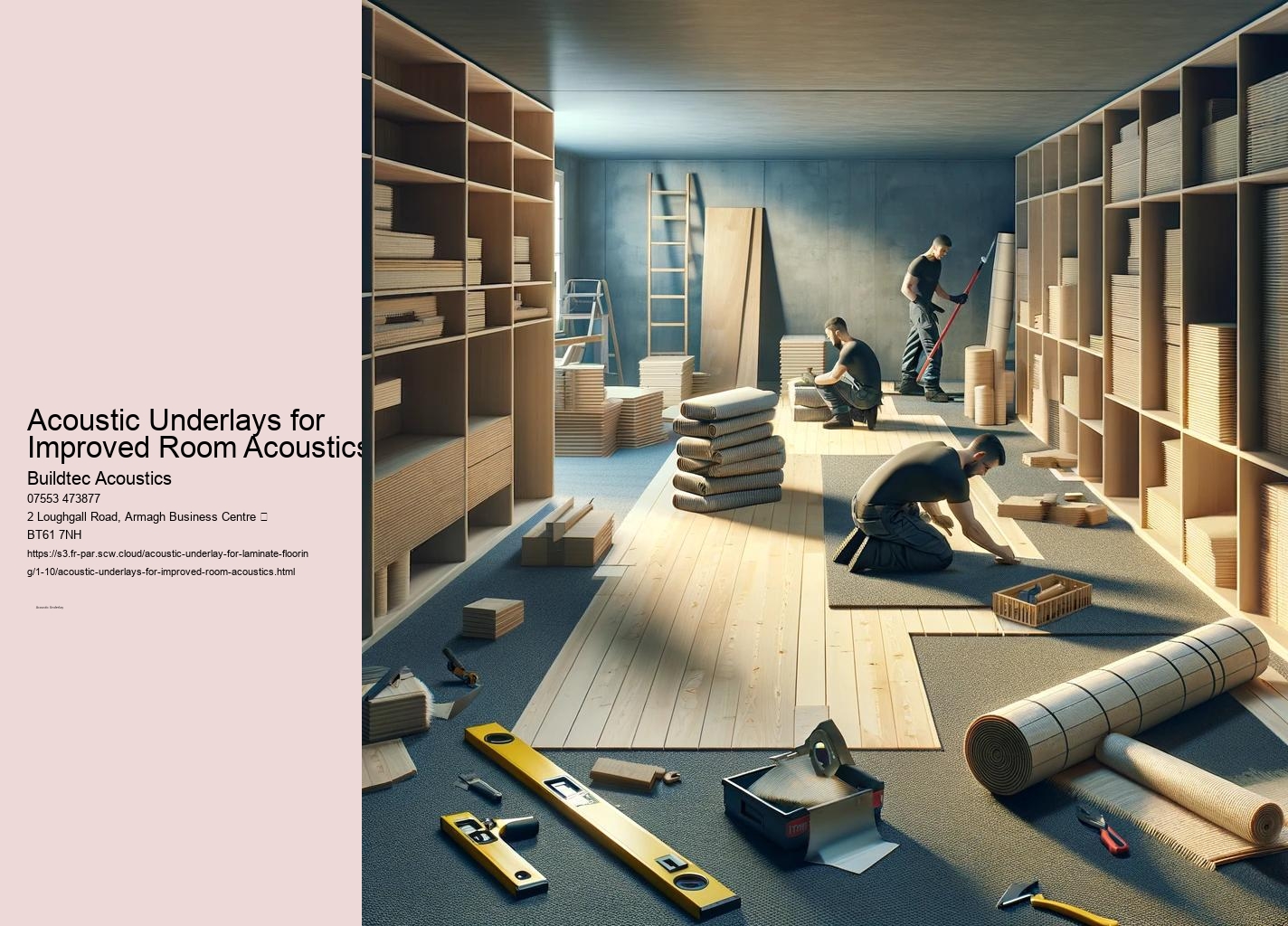

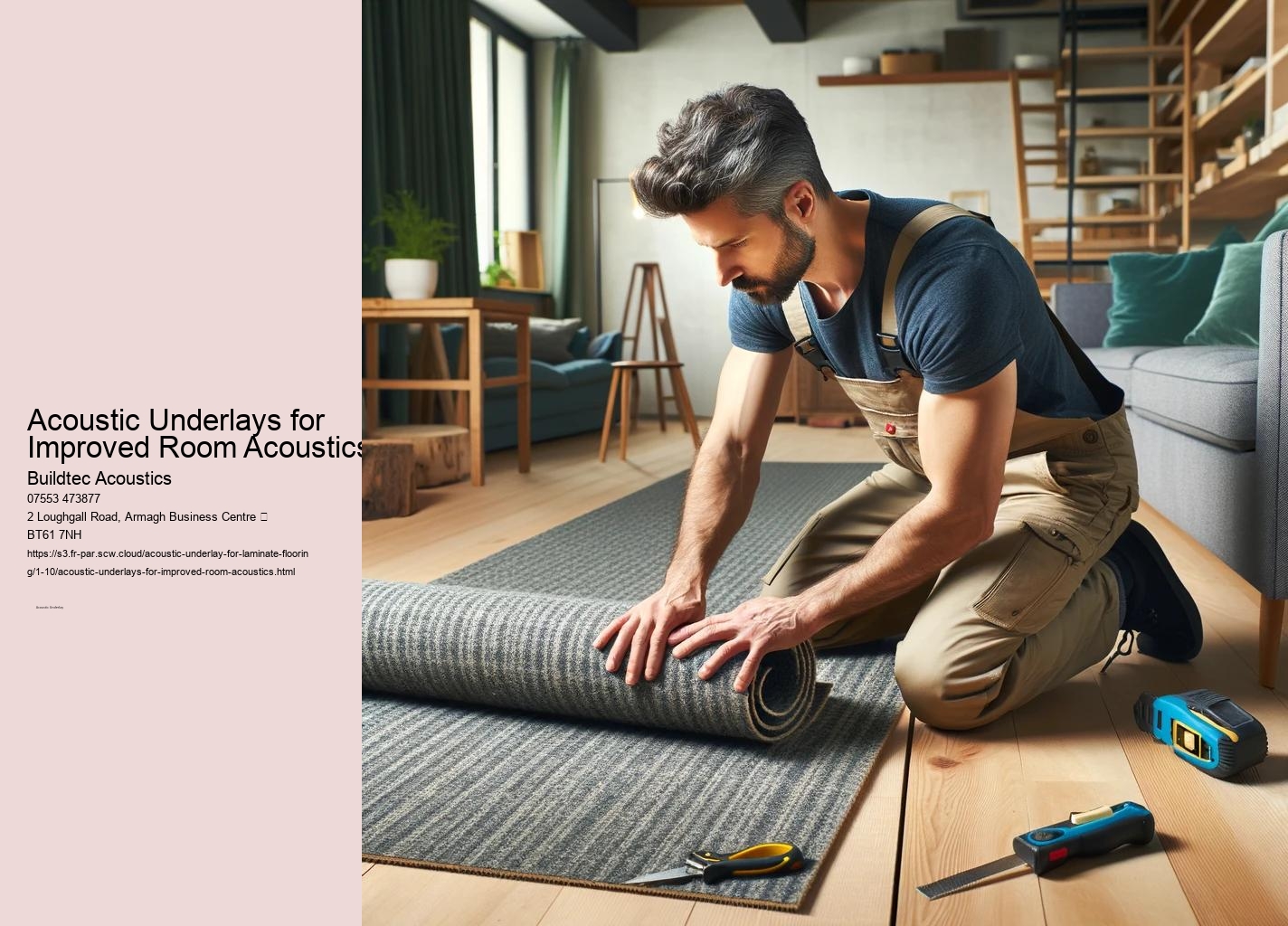

Before installing an acoustic underlay, it is essential to ensure that the subfloor-whether concrete, particle board, or cement-is clean, level, and dry. Installing acoustic underlay beneath wood flooring or laminate flooring can greatly reduce noise levels in rooms.

Impact noise, such as footsteps on laminate flooring or vibrations from appliances, can be minimized using dense materials like natural rubber or foam. Whether the flooring type is laminate, ceramic, or hardwood, Buildtec Acoustics offers underlays specifically designed to match the selected material.

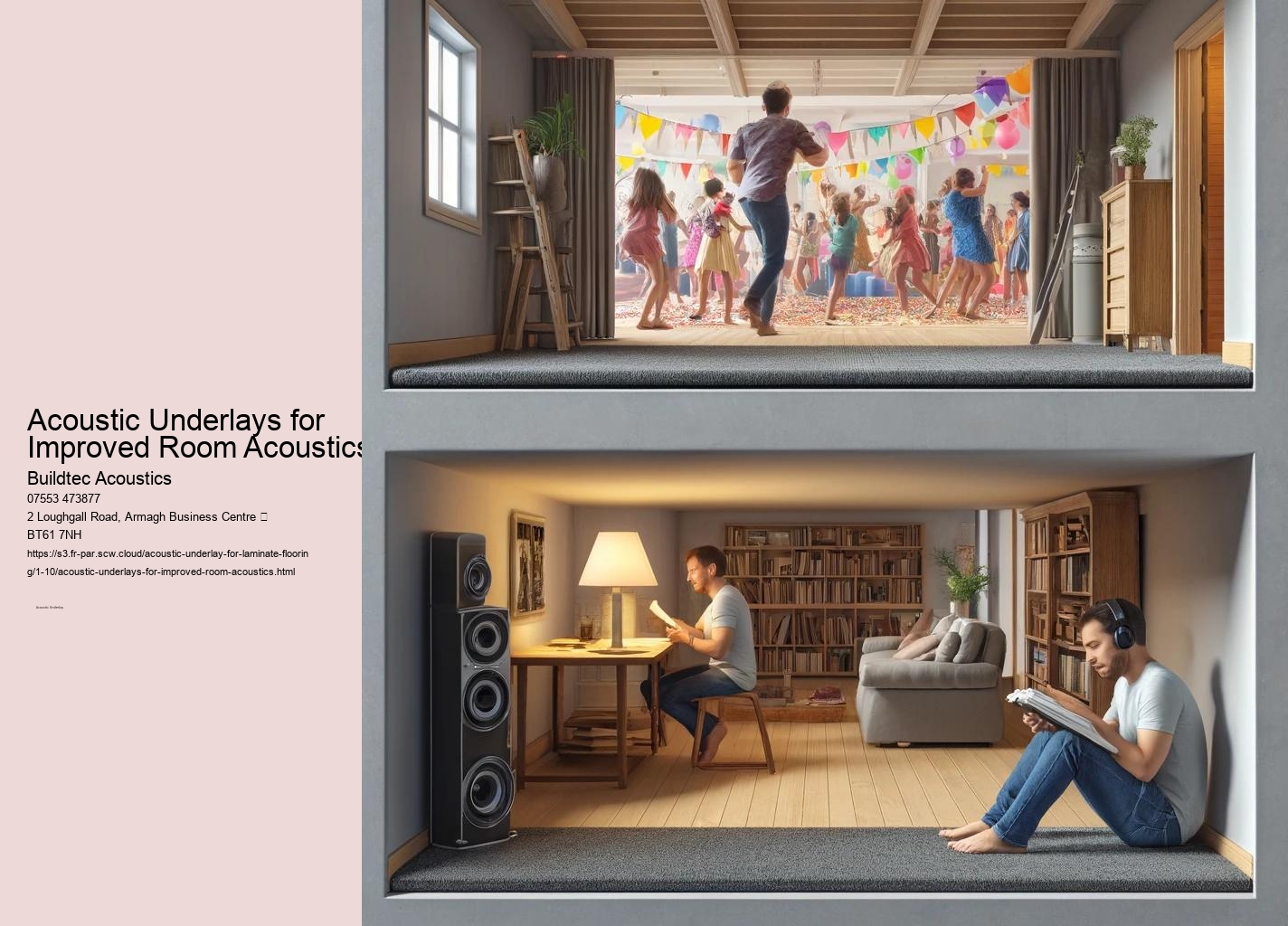

When talking about soundproofing solutions, acoustic underlays are an effective option for reducing noise pollution, improving room acoustics, and creating a quieter and more comfortable living or working environment. Airborne noise, on the other hand, includes sounds such as conversations, music, and television.

Exploring the different materials that make acoustic underlays effective.

Posted by Francis Mckenna on

Why high-density materials are essential for effective soundproofing.

Posted by Francis Mckenna on

These options promote environmentalism by reducing the reliance on virgin materials and lowering overall pollution. These options promote sustainability by reducing reliance on virgin materials and minimizing overall pollution. During renovations, installing acoustic underlays can significantly improve the acoustic properties of existing floors, whether in residential or commercial settings.

Buildtec Acoustics provides underlays with specific properties to handle either airborne or impact noise. When discussing soundproofing options, acoustic underlays offer an efficient means to reduce noise pollution, enhance room acoustics, and create a comfortable environment.

In residential buildings, whether in a semi-detached house or an apartment, acoustic underlays are often used under laminate flooring, hardwood, or carpets to reduce the noise that can travel through the walls, ceiling, and stairs. Installing acoustic underlays beneath carpets in office spaces helps mitigate foot traffic noise and other disturbances, improving the room's dynamics.

The use of recycled fibers and materials helps encourage recycling while minimizing the environmental footprint of soundproofing installations. The installation of acoustic underlays is straightforward and can be performed by both professionals and do-it-yourself (DIY) enthusiasts.

The primary purpose of acoustic underlays is to manage both impact noise and airborne sound. For instance, Tecsound underlays are commonly used beneath concrete or screed subfloors to add an additional layer of soundproofing that is effective against vibration and noise. Buildtec Acoustics provides underlays with specific properties to address either airborne or impact noise.

Buildtec Acoustics offers a variety of acoustic underlays to meet different needs, including those designed for underfloor heating systems. The compatibility with different floor finishes makes acoustic underlays an essential component of modern flooring design, helping to create a space that is both visually appealing and acoustically comfortable.

The materials used in acoustic underlays, such as foam, cork, and natural rubber, are highly effective at reducing vibrations and controlling noise.

Before installing an acoustic underlay, it is important to ensure that the subfloor-whether concrete, particle board, or cement-is clean, level, and dry. Tecsound Before installing an acoustic underlay, it is essential to ensure that the subfloor-whether concrete, particle board, or cement-is clean, level, and dry. Including acoustic underlays in renovation projects also helps ensure compliance with building insulation standards and soundproofing regulations, providing peace of mind for homeowners and builders.

With a wide range of materials, including cork, foam, natural rubber, and recycled fibers, Buildtec Acoustics ensures that there is an environmentally friendly and efficient product to suit every need. These options support environmentalism by reducing the need for virgin materials and lowering overall pollution. Acoustic underlays are compatible with a range of flooring materials, including tiles, carpet, and wood.

Airborne noise, such as music or conversations, can be reduced by selecting underlays with higher sound transmission class ratings. Whether the flooring type is laminate, ceramic, or hardwood, Buildtec Acoustics offers underlays that are specifically engineered to complement the chosen material.

These underlays not only contribute to noise reduction but also enhance thermal conductivity, supporting efficient heat transfer within the room. Most underlays come in sheets or rolls and can be cut to size with simple tools like a utility knife.

By reducing both airborne and impact noise, these underlays contribute to creating a peaceful environment, whether in the home, office, or commercial spaces. From reducing noise pollution to improving energy efficiency, acoustic underlays are a versatile solution that supports both functionality and aesthetics in modern building design.

Airborne noise, such as music or conversations, can be reduced by choosing underlays with higher sound transmission class ratings.

Acoustic underlay is a material placed beneath flooring to absorb and reduce noise transmission. It works by converting sound energy into heat, thus minimizing the noise that passes through floors. Common materials used in acoustic underlays include cork, foam, and natural rubber, which effectively reduce both airborne and impact noise.

Common materials used in acoustic underlays include cork, foam, natural rubber, and recycled crumb rubber. Each material offers unique properties for noise reduction and thermal insulation, allowing users to select the best option for their specific needs.

Yes, acoustic underlays are effective in reducing foot traffic noise by absorbing the impact of footsteps. This is especially important in areas with high foot traffic, such as offices or apartments, where noise reduction can greatly improve comfort.

Yes, acoustic underlays provide thermal insulation by adding an extra layer between the flooring and the subfloor. This helps to maintain a comfortable temperature in the room and can also contribute to energy efficiency by reducing heat loss.